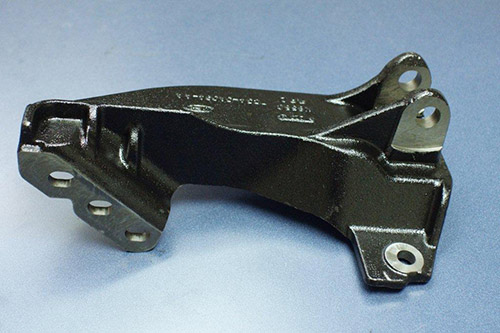

Precision CNC Milling of a Ductile Iron Steering Stabilizer

This large ductile iron bracket was designed for use as a steering stabilizer in an automotive application. Known as a track rod bracket, it’s composed of D65-45-12 Ductile Iron, and we manufacture 335,000 of these components per year for our customer in Michigan. Manufacturing requires the use of our state of the art precision CNC 4 axis horizontal machining cells which include an incoming conveyor, and robot load/unload features. This allows for the high volume and precision for the straddle milling, drilling, and slotting processes required for the fabricating these parts. The customer supplied drawings called out dimensions of 14.5″ in length, 8.5″ in width, 6″ in height, and tolerances of ±0.005″, with machined and E-coat finish. Quality throughout the production run is maintained through functional gauge checks. For more information, see the table below or contact us directly.

Highlights of this Precision CNC Milling Project

- Product Description

-

This Bracket is used to help Stabilize the Steering in Automobiles

- Precision CNC Milling Capabilities Applied/Processes

-

Primary:

CNC Milling

Drilling

Straddle MillingSecondary:

Slotting

- Equipment Used to Manufacture Part

-

Incoming conveyor

Robot load/unload

4 axis horizontal Machining cell

- Overall Part Dimensions

-

Length: 14.5″

Width: 8.5″

Height: 6″

- Tightest Tolerances

-

± 0.005″

- Material Used

-

D65-45-12 Ductile Iron

- Material Finish

-

e-coat and machined

- In process testing/inspection performed

-

Functional Gage Checks

- Industry for Use

-

Automotive Industry

- Volume

-

220,000pcs per Year

- Delivery Location

-

Michigan

- Standards Met

-

Customer Specifications, 2D CAD Drawing

- Product Name

-

Track Rod Bracket